OUR MILL

est. 2011 in the willamette valley

When Camas Country first opened its doors in 2011, we were the first mill of our kind to operate in the Willamette Valley in nearly eighty years. Grist mills once peppered the landscape of the valley, particularly along waterways, with mills in even the smallest communities. Over time, as the success of the seed industry pushed locally consumed grains to the margins, local mills also faded from the valley, and factory flour came to dominate pantry and grocery shelves across the Pacific Northwest.

REVIVING GRAIN MILLING

A COMMUNITY EFFORT

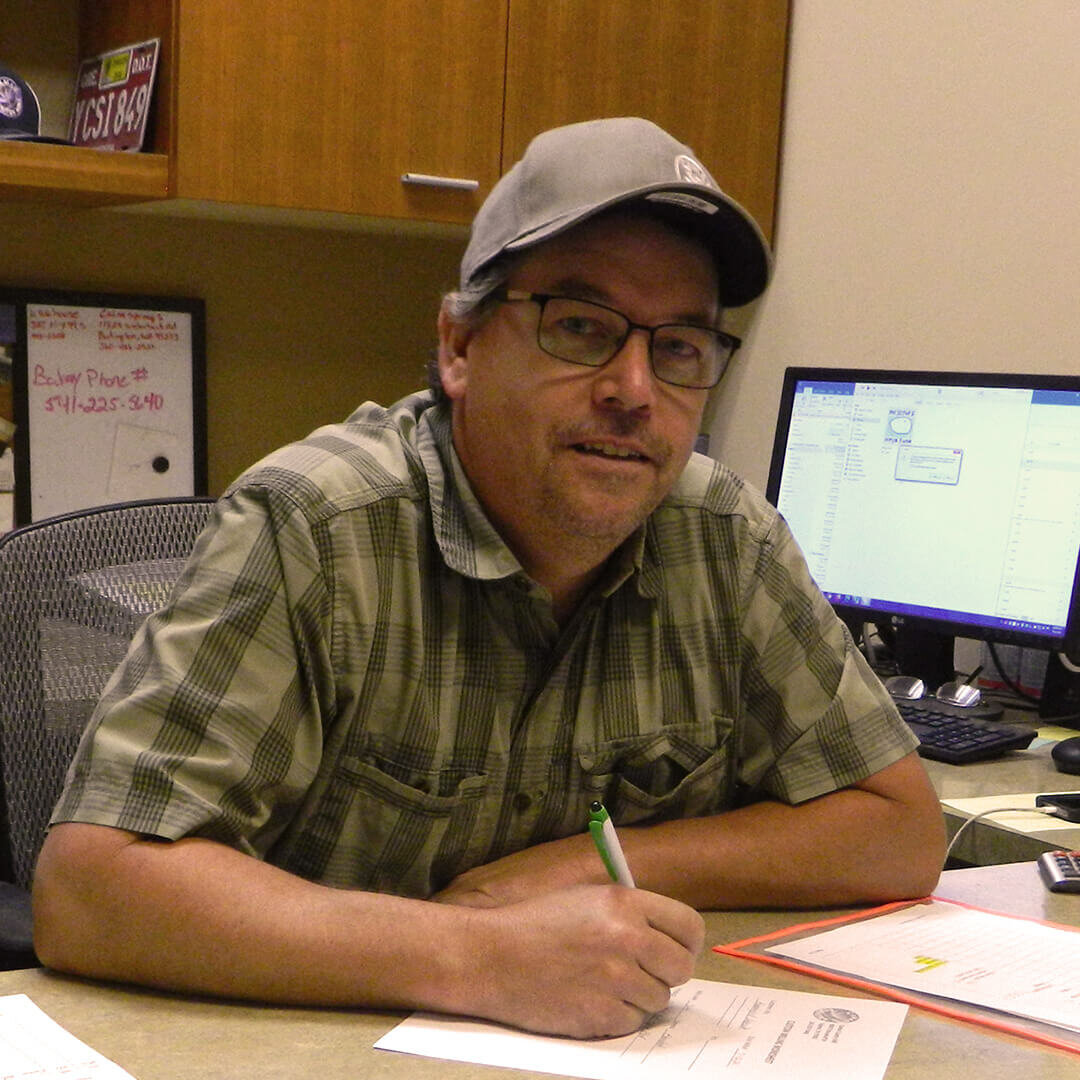

The first rumblings of a local mill enterprise started in Tom Hunton’s mind as commodity crop prices were buffeted by the stormy economy during the recession. Having raised grass seed, vegetable and cover crop seed, and wheat for export for decades, Tom decided it was time to diversify the family farm even further, and try something virtually unheard of for a mid-size valley farm—grow grain for the local and regional market. There is tremendous infrastructure set up in Oregon to get wheat and grain out of the state (in 2011, 85% of Oregon wheat was shipped overseas), but very little to keep it within the state.

Meetings with the Southern Willamette Valley Bean & Grain Project and consulting with university plant breeders led to wheat test plots on Hunton’s farm. Defying conventional wisdom, that first harvest proved that valley-grown hard red and white spring wheat had sufficient protein to meet the needs of commercial bakers. Not content to grow the grain and navigate financially and environmentally damaging shipping to a processor elsewhere, the Hunton’s decided to build their own mill. With the help of local distributor Hummingbird Wholesale and the city of Eugene, funding and strategy for the pieces of Camas Country Mill came together, and our doors opened in the spring of 2011.

Since then, more local and regional farmers have joined us in growing grains and legumes that are processed or packed at Camas Country, and over 2 million pounds of flour have run through our mill. We now supply 10 Oregon school districts with whole grain flour, as well as packaging a complete protein lentil-barley soup mix for our local food bank and supplying home and commercial kitchens throughout the West.

HOW THE MILL WORKS

STONE GRIST MILLS ARE THE MOST ANCIENT FORM OF FLOUR MILLS

Stone grist mills are the most ancient form of flour mills, with flour produced by the grinding of grain between stationary and rotating mill stones. In a stone mill, the entire grain kernel in its natural, original state is ground—bran, germ, and endosperm. The result is naturally whole grain flour with all of the inherent nutrition, vitamins, and minerals of the grain.

The vitamins and other essential nutrients lost in the conventional roller mill processing of white flours are concentrated in the bran and germ of the kernel, making the trade-off for white, fluffy flour a significant loss of nutrition and reliance on synthetic additives and fortifications. Our flours contain nothing more and nothing less than whole grains, thus providing our customers with a local, high-quality, and nourishing product that stands apart from others on the market.

Retail and Small Packaging Lead